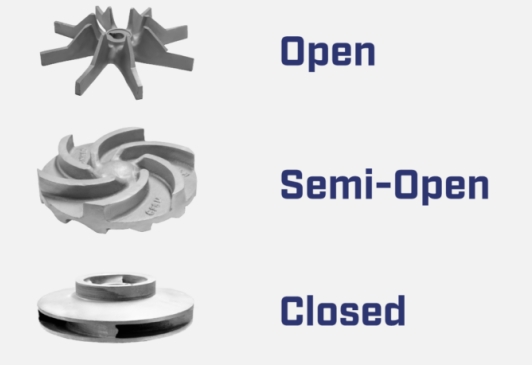

OPEN IMPELLER

There is no barrier in the vanes and easy to clean.It is usually mounted in the small pump with high speed.

But it it less efficient than closed impeller.

SEMI-CLOSED/OPEN IMPELLER

Semi-closed impeller have a back wall that adds strength to the impeller. It is used with liquids with solids. Reduced efficiency is a problem with semi-closed impellers, but the ability to pass solids is an important trade-off.

CLOSED IMPELLER

A closed impeller is constructed with additional wall sections on the back and front sides of the vanes, giving it greater strength. This also reduces the thrust load on the shaft, increasing bearing life and reliability and reducing shafting costs. Due to this more complex design, closed impellers are more difficult to manufacture and more expensive than open impellers. As the wear ring clearance increases, the efficiency of a closed impeller decreases. Closed impellers work better in a wider range of speeds than open impellers. Used primarily in large-scale pumps and for clear water, these impellers can't perform effectively with solids. If they get clogged, it becomes difficult to clean them.

DIFFERENCES

When buying a centrifugal pump, we always look for pumps with high efficiency, minimal maintenance and good reliability. One must always consider all these factors, however, one thing that people forget to look at is selecting the right impeller style for your centrifugal pump. Earlier, impellers generally were divided into two categories open and closed. But these days, there is also a third type available. It is called a semi-open impeller. Here are a few differences between the open and closed impeller:

Closed impellers are the most commonly used impellers in the industry since they can deal with volatile and explosive fluids.

The closed impeller is initially really efficient, but with time, loses its efficiency as the clearance of the wear ring increases, whereas the efficiency of an open impeller can be maintained through clearance adjustment.

The pump had to be disassembled when it has a closed impeller to check the status of the wear rings. In an open impeller, no pump disassembling is necessary.

An open impeller is less likely to get clogged and even if it does, it is easier to clean whereas in a closed impeller, if stringy material or solids are pumped, the impeller can clog and it becomes really difficult to clean them.

The internal parts of a closed impeller are hidden hence it is difficult to cast and inspect for flaws whereas in an open impeller, all the parts are visible. It thus becomes easy to inspect for damage.

The design of a closed impeller is more complicated and expensive since the additional wear rings are needed while the open impeller is less costly to build.

You cannot easily modify a closed impeller so as to improve its performance. While the vanes can be easily cut to improve the capacity in an open impeller.

In a closed impeller, speed choices are limited. But you have a wide range of specific speed, choice is an open impeller.

Previous article:Cartridge type mechanical seal description

Next article:no more