IHZ STAINLESS STEEL STRONG SELF-PRIMING PUMP

Product overview

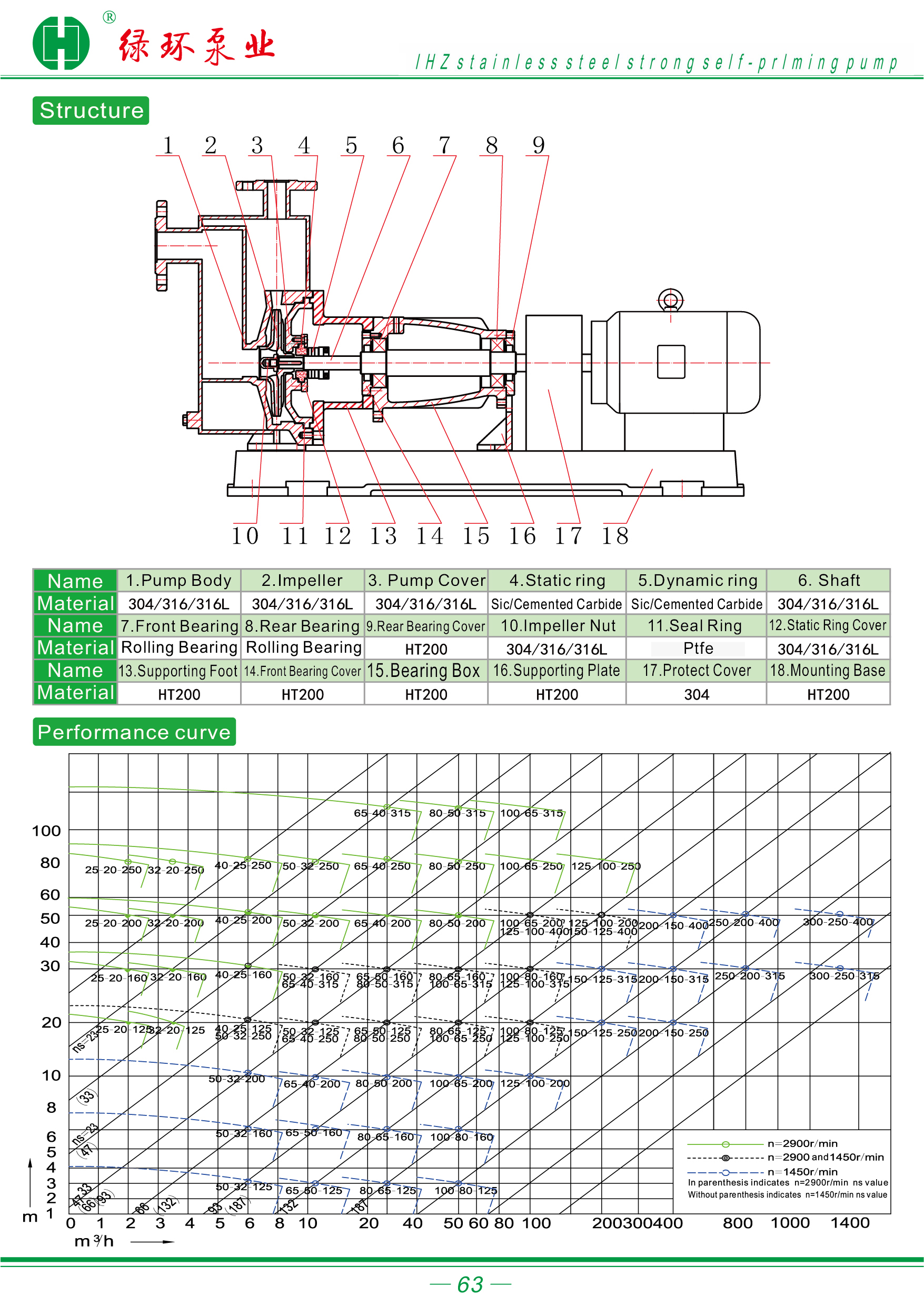

IHZ stainless steel strong self-priming pump (referred to as: Self-priming pump) is a technology designed by LVHUAN company in accordance with national standards, combined with the process design and manufacture of IHL pump, pump body by suction chamber, liquid storage chamber, volute, backflow hole, gas-liquid separation chamber and so on. Pump starts under the action of centrifugal force, the remaining liquid in the suction chamber and the air in the liquid inlet pipe are stirred into a gas-liquid mixture by the impeller, and the mixture enters the gas-liquid separation chamber through the volute. As the flow rate slows down, the gas-water separation is caused, the air is discharged from the pump outlet, and the liquid returns to the pump through the water backflow hole. After several cycles, the air in the liquid inlet pipe is discharged, so that a certain vacuum is formed in the pump. The external mounted tetra fluoro bellows mechanical seal used in the pump can be equipped with a hard to hard (silicon carbide to silicon carbide) mechanical seal without cooling water when conveying media containing impurities particles, so the user needs to take into account the solid content in the medium when selecting.

Design feature

1, IHZ self-priming pump is based on IS02858/ GB5662/DIN24256 international standards, the centrifugal pump and self-priming centrifugal pump performance combined, self-designed and developed strong self-priming industrial pump.

2, the pump body, impeller and pump cover using CFD computational fluid mechanics, design hydraulic parts, module design and precision casting. It has the characteristics of high efficiency, good cavitation residual performance, small radial force, accurate size, good interchangeability, spacious and smooth flow path, etc.

3, the shaft seal is an internal single end mechanical seal, the sealing surface of the grinding can be selected: Silicon carbide, carbide and other materials, can be selected according to the requirements of the double end mechanical seal and external mechanical seal, in order to meet the requirements of various working conditions.

4, the international standard shaft pull back design, no need to disassemble the pipe, easy maintenance;

5, horizontal installation, low vibration, low noise, stable operation, international standard design, can be exchanged with standard chemical centrifugal pump, easy to replace and use;

6, gas-liquid mixed self-priming design, with strong self-priming function, self-priming height up to 5.5m;