LZC stainless steel self-priming magnetic pump

Product overview

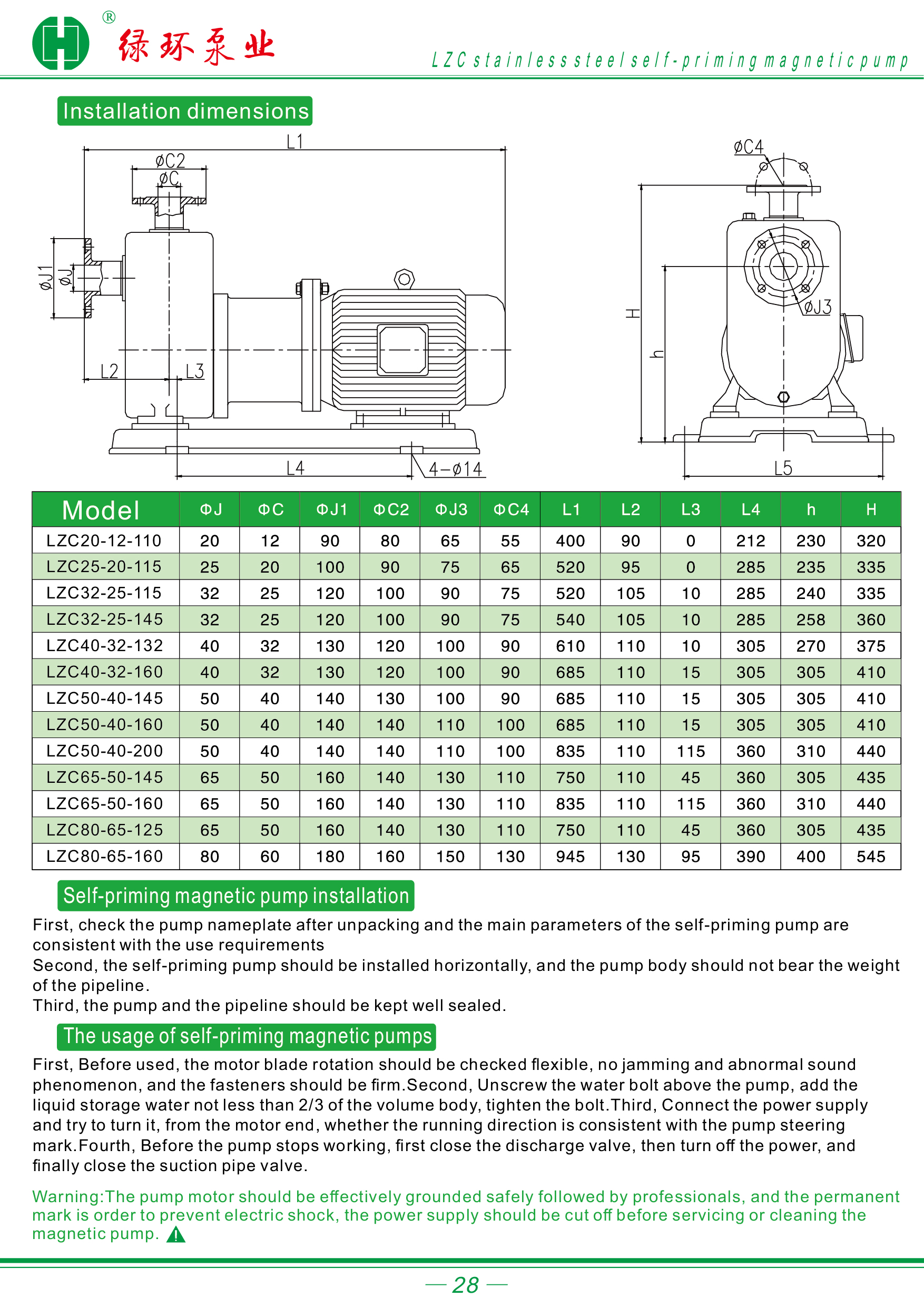

LZC self-priming magnetic drive pump is on the basis of CQ magnetic pump to absorb the excellent technology, through the repeated research and test , its performance has reached the advanced level. LZC self-priming magnetic drive pump to static seal instead of dynamic seal, so that the flow parts in a completely sealed state, to solve the other pump mechanical seal, the inevitable running, bubbling, dripping, leakage of the ills, the pump body and flow parts are made of corrosion-resistant stainless steel, ceramic, PTFE graphite, carbon graphite, carbide and other materials. It has the function of LCQ type magnetic pump and integrates self-suction without bottom valve and irrigation water, open and pump, easy and convenient.

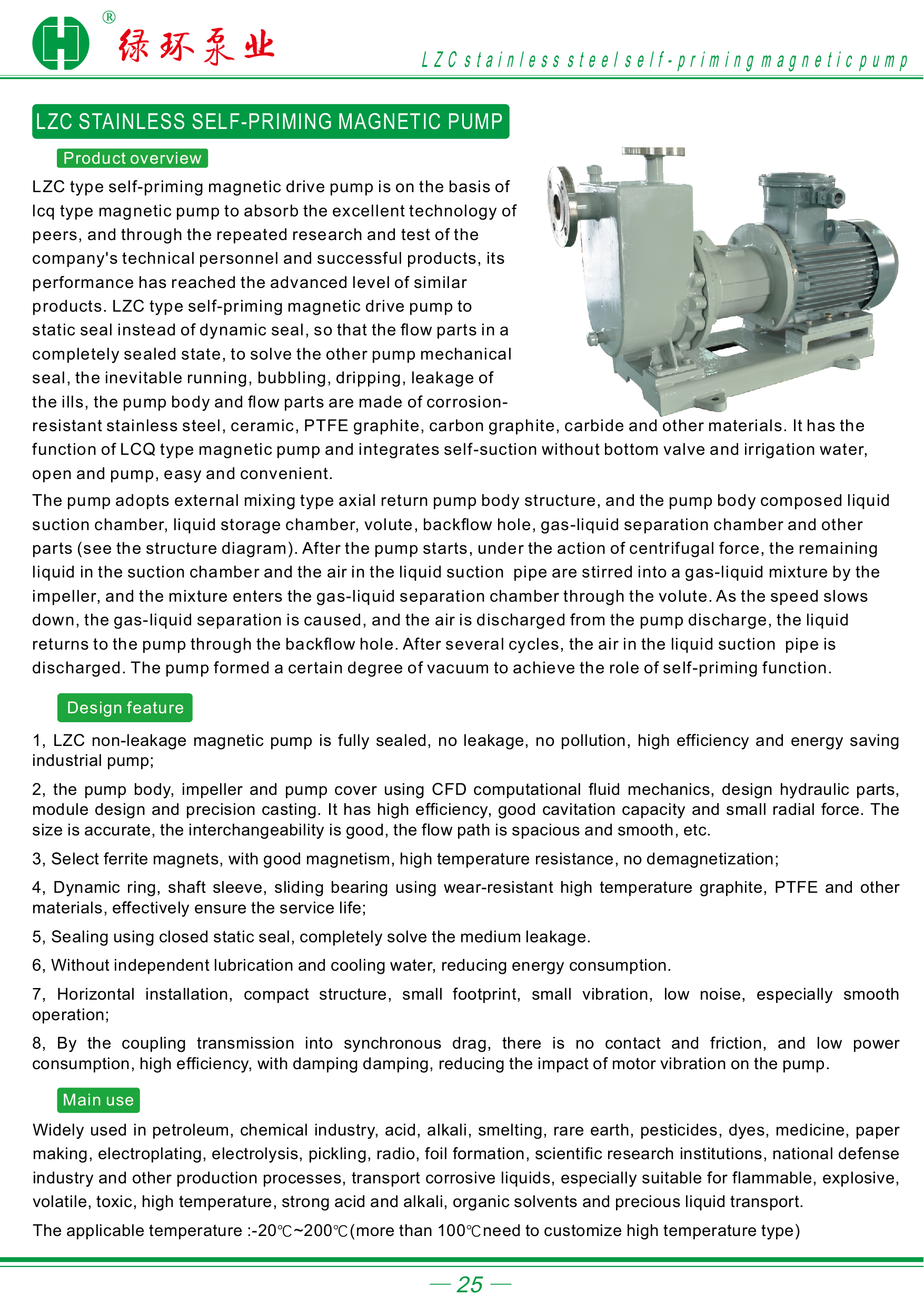

The pump adopts external mixing type axial return pump body structure, the pump body composed liquid suction chamber, liquid storage chamber, volute, backflow hole, gas-liquid separation chamber and other parts (see the structure diagram). After the pump starts, under the action of centrifugal force, the remaining liquid in the suction chamber and the air in the liquid inlet pipe are stirred into a gas-liquid mixture by the impeller, and the mixture enters the gas-liquid separation chamber through the volute. As the speed slows down, the gas-liquid separation is caused, and the air is discharged from the pump outlet, the liquid returns to the pump through the backflow hole. After several cycles, the air in the liquid inlet pipe is discharged. The pump formed a certain degree of vacuum to achieve the role of self-priming function.

Design feature

LZC non-leakage magnetic pump is fully sealed, no leakage, no pollution, high efficiency and energy saving industrial pump;

the pump body, impeller and pump cover using CFD computational fluid mechanics, design hydraulic parts, module design and precision casting. It has high efficiency, good cavitation capacity and small radial force. The size is accurate, the interchangeability is good, the flow path is spacious and smooth, etc.

Select ferrite magnets, with good magnetism, high temperature resistance, no demagnetization;

Dynamic ring, shaft sleeve, sliding bearing using wear-resistant high temperature graphite, PTFE and other materials, effectively ensure the service life;

Sealing using closed static seal, completely solve the medium leakage.

Without independent lubrication and cooling water, reducing energy consumption.

Horizontal installation, compact structure, small footprint, small vibration, low noise, especially smooth operation;

By the coupling transmission into synchronous drag, there is no contact and friction, and low power consumption, high efficiency, with damping damping, reducing the impact of motor vibration on the pump.

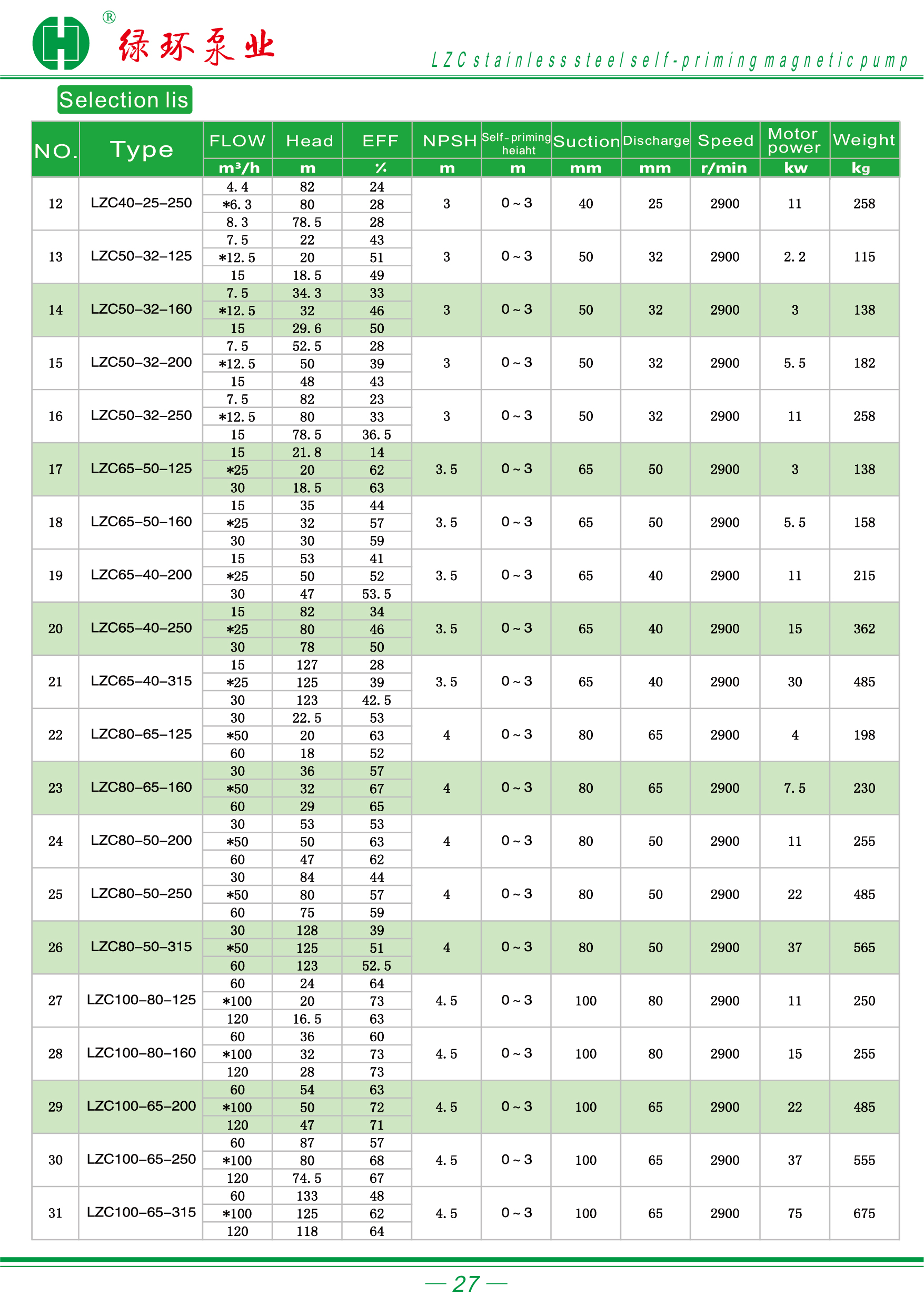

Self-priming magnetic pump installation

First, check the pump nameplate after unpacking and the main parameters of the self-priming pump are consistent with the use requirements

Second, the self-priming pump should be installed horizontally, and the pump body should not bear the weight of the pipeline.

Third, the pump and the pipeline should be kept well sealed.

The usage of self-priming magnetic pumps

First, Before used, the motor blade rotation should be checked flexible, no jamming and abnormal sound phenomenon, and the fasteners should be firm.

Second, Unscrew the water bolt above the pump, add the liquid storage water not less than 2/3 of the volume body, tighten the bolt.

Third, Connect the power supply and try to turn it, from the motor end, whether the running direction is consistent with the pump steering mark.

Fourth, Before the pump stops working, first close the discharge valve, then turn off the power, and finally close the suction pipe valve

Warning:The pump motor should be effectively grounded safely followed by professionals, and the permanent mark is order to prevent electric shock, the power supply should be cut off before servicing or cleaning the magnetic pump.