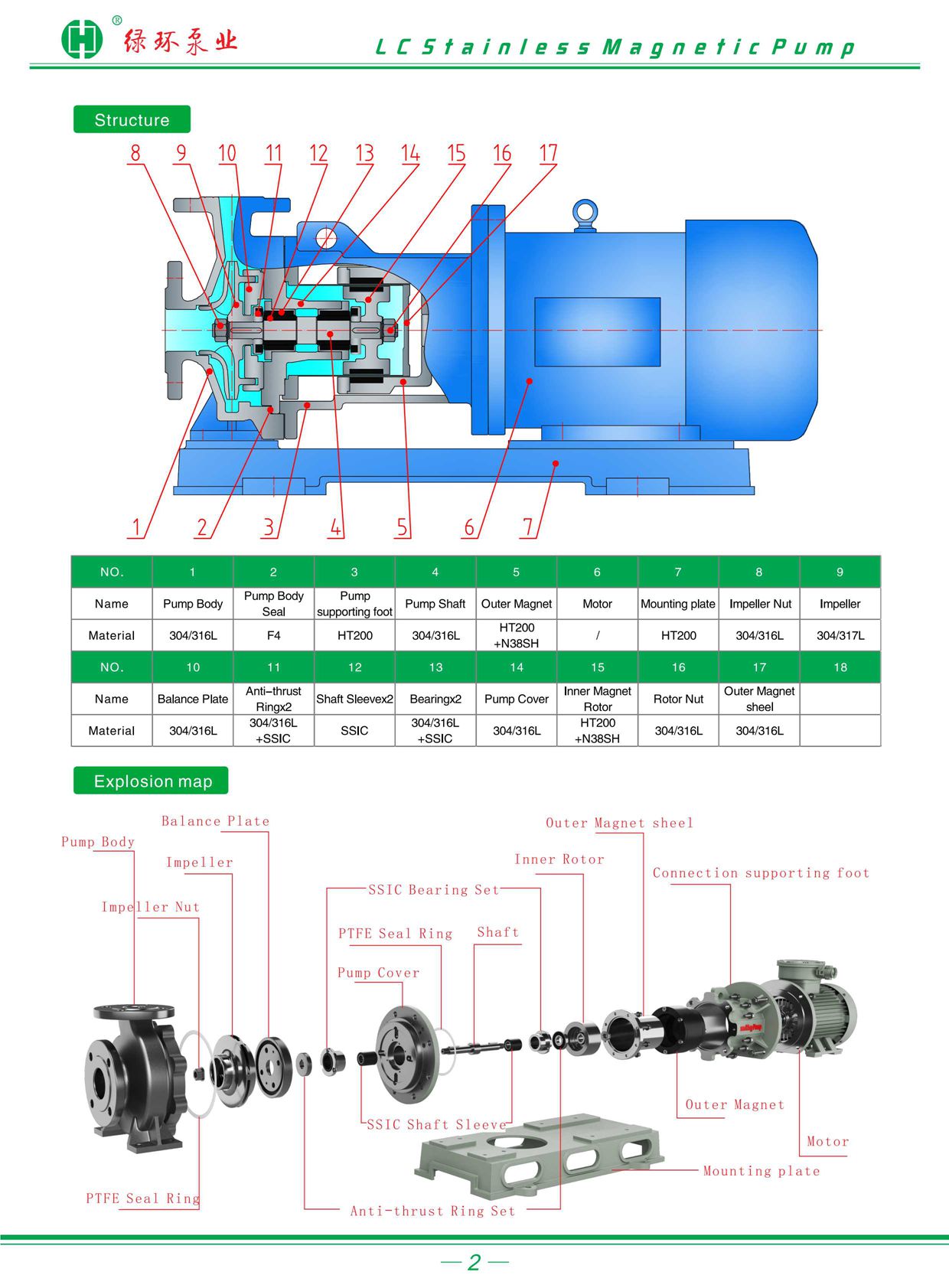

Description:Heavy-duty structure design, axial force self-balance, dynamic and static ring can be easily replaced, magnetic steel according to the working condition free combination, all components have strong versatility, modular design.

Pump body:ISO2858 standard pump body

Impeller:Silica sol precision casting, higher water efficiency (with front and rear mouth rings)

Pump cover:The special process is used for transition. The bearing seat with SSiC bearing, which is highly wear-resistant and can be easily replaced

Anti-thrust ring: Designed with anti thrust ring assembly and steel wire retaining ring design, it can be easily replaced independently. The impeller and rotor is independent.

Pump shaft: Lengthened 304 pump shaft + expansion sleeve +SSiC sleeve design, with the "SiC bearing" On the pump cover to wear support, hard to hard match, extremely long life, and not limited by temperature, its deformation is buffered by the expansion sleeve.

Inner rotor: The magnetic steel design according to different working conditions, arbitrary combination, inner rotor diameter is small, axial length, higher efficiency of transfer torque, and magnetic loss is almost zero.

External rotor: Multi-stage magnetic steel design can be combined to different working conditions, due to the small outer diameter, the outer magnetic barrel is thicker, separate external magnetic pressure plate, completely eliminate magnetic leakage.

Special structure design: LC has self-balancing device, can use water self-balancing impeller, life increased for more than 3 times.

DESIGN FEATURE

A. MAGNETIC CIRCUIT DESIGN:

1. Push-pull magnetic circuit design is adopted to achieve the highest transmission efficiency of internal and external magnetic torque.

2. Rational design of magnetic angle to maximize magnetic energy utilization;

3. Using a reasonable number of magnetic poles increase the static magnetic energy, more kinetic energy is converted, the magnetic

blocks is less under the same torque;

4. The yoke iron design is adopted, the yoke thickness iron is increased to avoid magnetic saturation, reduce magnetic resistance,

increase the magnetic density of the air gap, increase the transmitted torque, improve the performance of the internal magnetic rotor by 120%;

5. The magnetic tile is arranged in multiple groups, the heteropolar alternating group method is adopted, and the eddy current is closed between

each pole, forming m*z small eddy current (z row number of magnetic poles, m number of magnetic poles) eddy current loss is greatly reduced.

DESIGN FEATURE

A. Magnetic circuit design:

1. Push-pull magnetic circuit design is adopted to achieve the highest transmission efficiency of internal and external magnetic torque.

2. Rational design of magnetic angle to maximize magnetic energy utilization;

3. Using a reasonable number of magnetic poles increase the static magnetic energy, more kinetic energy is converted, the magnetic blocks is less under the same torque;

4. The yoke iron design is adopted, the yoke thickness iron is increased to avoid magnetic saturation, reduce magnetic resistance, increase the magnetic density of the air gap, increase the transmitted torque, improve the performance of the internal magnetic rotor by 120%;

5. The magnetic tile is arranged in multiple groups, the heteropolar alternating group method is adopted, and the eddy current is closed between each pole, forming m*z small eddy current (z row number of magnetic poles, m number of magnetic poles) eddy current loss is greatly reduced.

B, AXIAL FORCE SELF-BALANCING DESIGN

1. When the pump is running, as the internal pressure chamber changes with the change parameters, the impeller is always in a floating state, the ordinary magnetic pump only uses the "Thrust disc" to hinder the axial force friction .

2. The LC magnetic pump adopts a unique axial force balance design. The balancing device is equipped with a balance disc, balance seat, front and rear double ring, a pressure accumulator chamber. The axial force is automatically balanced by hydraulic power. With the changing axial position of the impeller rotor components, the covered area balance hole will also change, which will automatically affect the pressure of the balance chamber.

3. For example, when the impeller rotor component shifts towards the suction direction, the opening degree of the "Control valve" Automatically increases, the overflow rate of the balance hole increases, the balance chamber pressure decreases,acting on the back cover of the impeller decreases, while the front cover pressure remains unchanged, at this time the thrust direction changes, so that the impeller rotor component returns to the balance position, and vice versa.Thus,the axial force can achieve self-balance through hydraulic power, and self-balance design makes the LC magnetic pump sliding bearing and the thrust disk almost no "Friction", and the sliding bearing is close to zero load, effectively ensuring the stable operation and service life .

4. Due to flow changes, density changes, viscosity changes, temperature changes and other factors, the internal axial force will change, through the self-balancing device and under the interaction, the impeller rotor components will achieve self-balance, so that its position is always in the balance point, therefore, the LC pump using the device maximizes the working range. The adaptability to enhance different media and working conditions.